This is the AnyCubic Photon Mono M5S, and in this article, I’m going to share 5 reasons that it’s one of the most cutting-edge consumer resin printers on the market today.

Let’s dive in.

Background

First things first, a little background, and let’s get the disclaimers out of the way.

This unit was provided to me for free for review, so that I could assess the quality of AnyCubic’s products and service before accepting them as a video sponsor.

They haven’t had any creative control whatsoever, or seen the review video before you have, and the opinions in this video ARE my own, but, I of course can’t call it a product review because money has changed hands, so think of it as more like an overview.

With all that said, I have to say that like my contemporaries Joel Telling and Uncle Jessy, I’ve been seriously impressed with this printer, and in a lot of ways, it’s been a redeeming experience for resin 3d printing as a whole.

Many of you – though not that many, because the video seems to have bombed – might remember that I recently tried Resin 3D printing for the first time, and while I was all cheery and optimistic when I recorded the video, I had plenty of spills and horror stories by the time the video went into editing.

So as you can imagine, I was a little wary when this big boi of a resin 3D printer showed up on my door – especially given that unlike the model I tested in that previous video, this is NOT marketed as a “beginners” unit – but rather, serves as the new “top of the line” for AnyCubic, coming in at a respectable $499.

That might not seem like a lot, if you’re an FDM person like me, but with many of Anycubic’s models selling for $189-299, this model is quite far out there in terms of price range.

But here are some reasons why that price just might be justified:

Huge 12K Display

Whether or not you’re into resin 3D printing, you’ve probably seen a lot of ads for “8K” resin 3D printers.

As I understand it, some of that is a bit misleading, because what really matters is the pixel density, that is, resolution over area… but with this printer, you’re not only getting a pretty large 10.1” display, you’re also getting an industry-first 11,520 x 5,120 pixel display to back it up.

That means that despite the large size of the screen compared to other resin 3d printers, you’re not compromising on resolution. And so far, from my testing, that has definitely been true.

Ridiculous Speeds

One of the features I didn’t anticipate with this printer was the ridiculously fast speeds it achieved.

Now, keep in mind, I don’t know much about what’s available on the market in the resin scene – but I was surprised to see that even Uncle Jessy – who I consider to be quite an expert on all things resin 3D printing, called this the fastest resin printer he’d ever seen.

And let me tell you – it really IS fast.

They accomplish this in a few different ways.

First, they use a high-speed release film, that allows you to peel off new layers way faster – like, 1 second fast.

Second, they use a high-speed resin that has a viscosity closer to water than the usual goopy resin. Side note, it also has WAY less of a god-awful toxic smell to it than the stuff I was using before.

Third, they have the default profiles set to 0.1mm , which, although it might seem tiny for us FDM folks, is really huge in 3D Printing. You can barely see it in the models, because the details are otherwise so crisp, and it essentially means that you can print a staggering 105mm an hour.

Check out this video I took to demonstrate its speed:

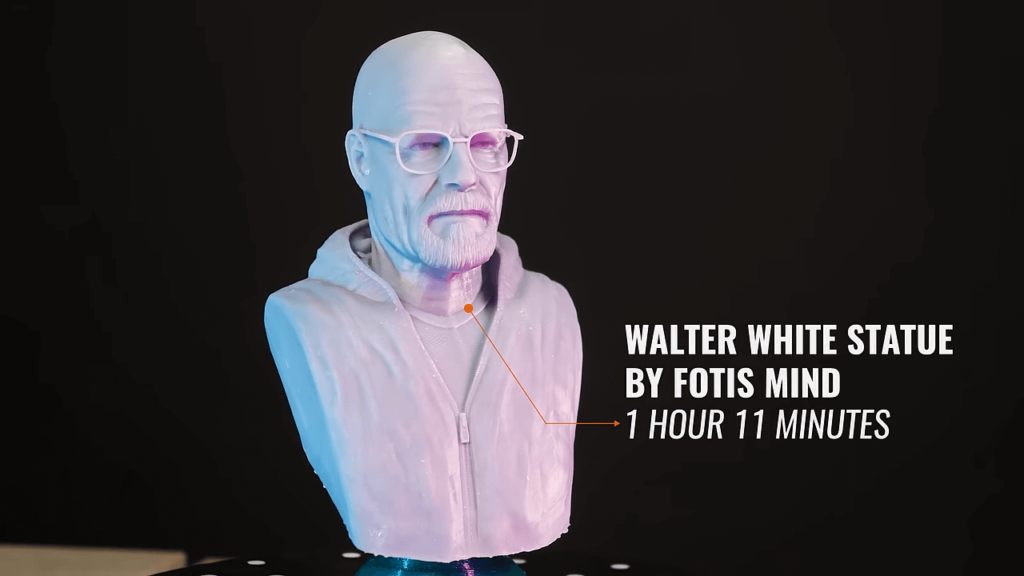

Just look at these models, and the times they took to print:

Model of Jonathan by PrintedObsession: 1 hour 50 minutes

Dragon by PrintedObsession: 1 hour 54 minutes

Walter White Statue by Fotis Mind : 1 hour 11 minutes (bust only)

No Bed Leveling

Here’s another cool one, which, given my limited experience with resin, if I hadn’t seen Uncle Jessy talk about it, I probably wouldn’t realize that it’s a big deal.

In the FDM world, we’re very much used to automatic bed leveling. But as it turns out, in consumer resin printing, this is a truly unique feature. If you remember back to my last foray into resin, I had a lot of prints – including my first few – fail because of improper bed leveling.

So for this printer to do all of that automatically every time is pretty sweet… and yes, it actually works. When I’d written this, I had 0 print fails. Though now I know well enough that if I SAY I have no print fails, I’ll have print fails, and yes, I had a print fail right after writing this – due to user error.

It’s Smart

So, when you boot this thing up, it does all kinds of automatic checks, and that’s pretty cool.

But here’s another head-scratcher for you guys. AnyCubic claims that this printer can detect whether or not there is enough resin in the vat to complete the print.

OK, fine, so it probably has some kind of scale in there, right? But get this; it can also detect if there are print failures mid-print, I guess maybe by sensing if the weight in the vat increases abruptly during printing, or if it’s not decreasing at the predicted rate with resin getting cured and lifted out of the vat?

Look, I don’t know how it works, but I have to say that this is a welcome feature, especially because unlike many FDM printers today, Resin 3D Printers don’t typically have an integrated camera where you can check in on your print and stop it if things are looking funky.

Which, actually, is a great segue into my next point:

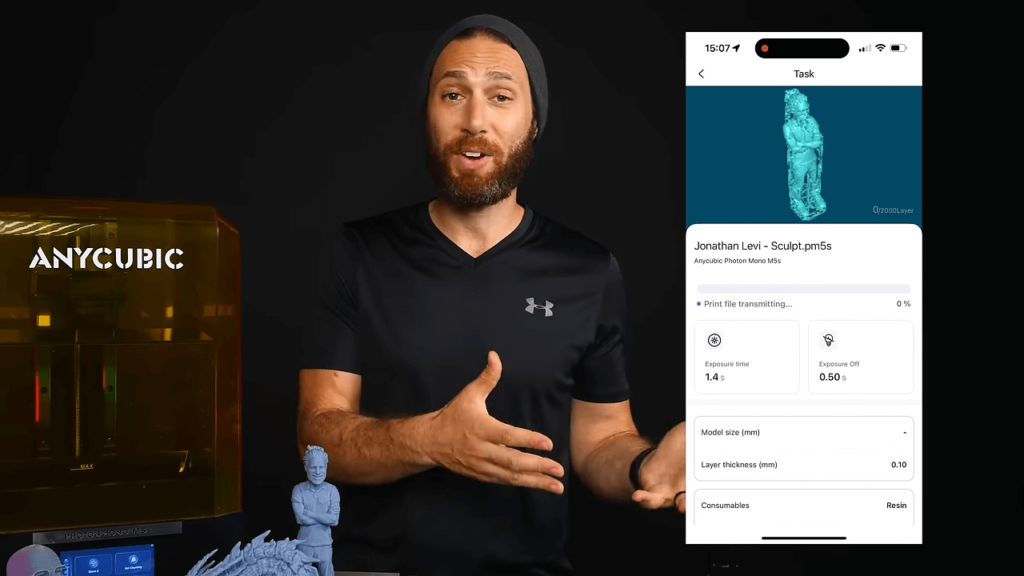

Connectivity & Interface

One of the things that was missing for me with the “beginner” model I tried out in my last resin video was the ability to transmit files to the printer directly over wifi or a cloud service.

I know, I know, a lot of you guys hate cloud services, but for me, going back and forth with a USB stick was way worse, because it wo uld inevitably get resin on it, and then I didn’t want to handle it without gloves, but I also don’t want to get resin-soaked gloves anywhere near my computer.

Fortunately, this printer has Wi-Fi connectivity, and works through AnyCubic’s cloud service, which, although it’s really, really slow for some reason, is available via a smartphone app or the desktop slicer.

Which leads me to:

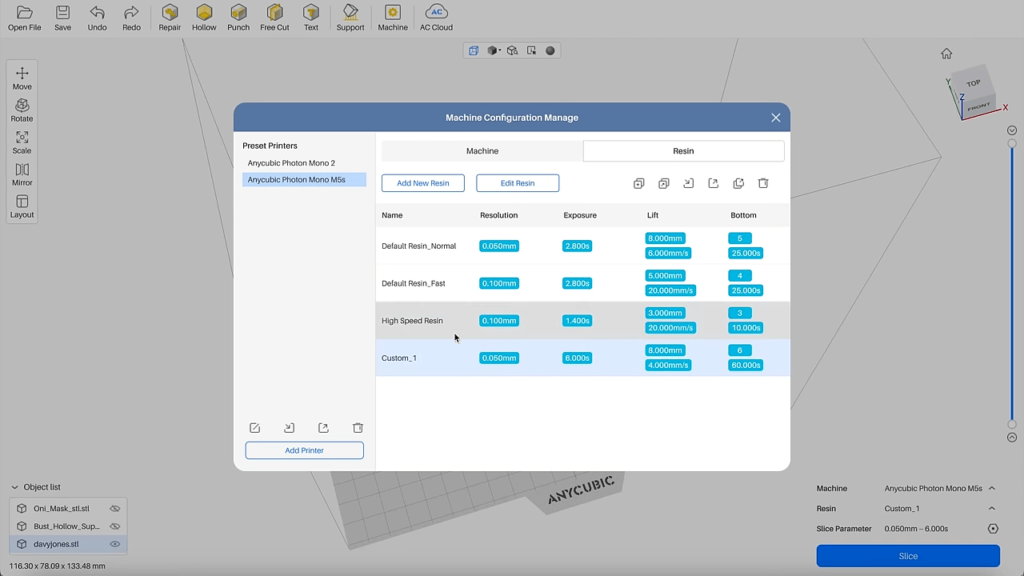

AnyCubic Photon Workshop

I’ll be honest and say that when I started using AnyCubic’s slicer, instead of the paid options out there like ChituBox or Lychee that everyone recommends, I was a little embarrassed. But hear me out: this slicer is actually really good – and I’m not the only one who thinks so.

AnyCubic has put in a good amount of work into making it advanced for advanced users, and simple for simpletons like me, plus, they’ve added an “intelligent” mode, which does all kinds of advanced tweaks to improve your prints.

Plus, they have all the profiles for their printers and resins in there, which is super convenient – kind of like using PrusaSlicer for your Prusa printer printing Prusament.

So yeah, I really like this slicer, and I’m gonna keep using it.

Conclusion

So, what can I say – I really like this printer.

I actually, genuinely like it, and like using it.

Whereas, after publishing my last video, I had some significant, shall we say, “mishaps” that made me question whether or not I want to keep learning about resin 3D printing, The M5S has made me excited to go back into the rabbit hole and continue my journey.

It kind of just works – except when you have user error issues like I did, it prints beautifully, and while it can’t mitigate the “pain in the butt” parts of resin 3D printing like dealing with uncured resin, it makes all the other stuff, like slicing files, printing at high quality, and detecting failures as simple as can be.

Truthfully, this printer, like the Bambu Lab X1 Carbon, makes me ask: is it still the right call to recommend that beginners start out with a lower quality printer? with less intelligence and fewer features?

Do beginners still need to go through that educational rite of passage of learning how the printer works by repairing it, or are we on the brink of an era of “it just works” printers, such that we should instead just recommend beginners in the hobby go straight for these smarter, more advanced machines, if their budget allows for it?