For the last few weeks, I’ve been playing around with this 30W desktop CO2 laser.

In this article, I’m going to share what I learned, an overview of what it can do, and answer the question on every 3d printing maker’s mind – Should you get one, too?

Let’s dive in.

Background

Ever since my YouTube channel started gaining traction, my inbox has been absolutely flooded with offers of every kind of laser, from big, enclosed, fricken’ laser beams, to add-on diodes for 3D Printers, to massive open-air suckers with work areas about as big as I am. Which, I guess, isn’t saying all that much.

Fortunately, I discovered a video from Angus at Maker’s Muse early on, which informed me that open lasers were more dangerous than literal sharks with fricken lasers attached to their heads – and so, with two young kids at home and a tiny office space with poor ventilation, I’ve been passing up on all of these review units.

What can I say? Call me sentimental, but I like that my kids can see.

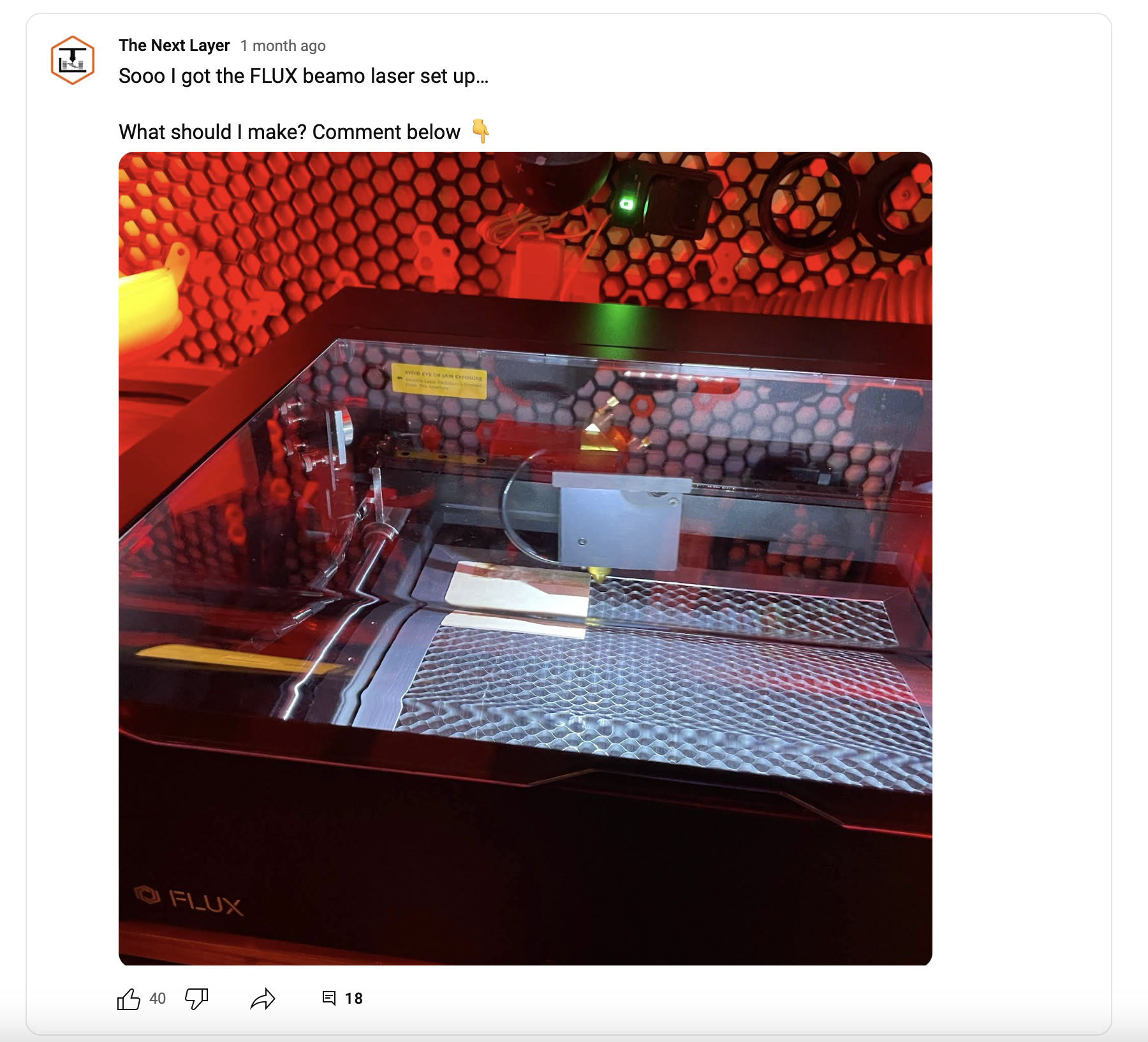

So imagine my schoolboy-esque excitement when I stumbled upon the Taiwanese company FLUX at FormNext 2022.

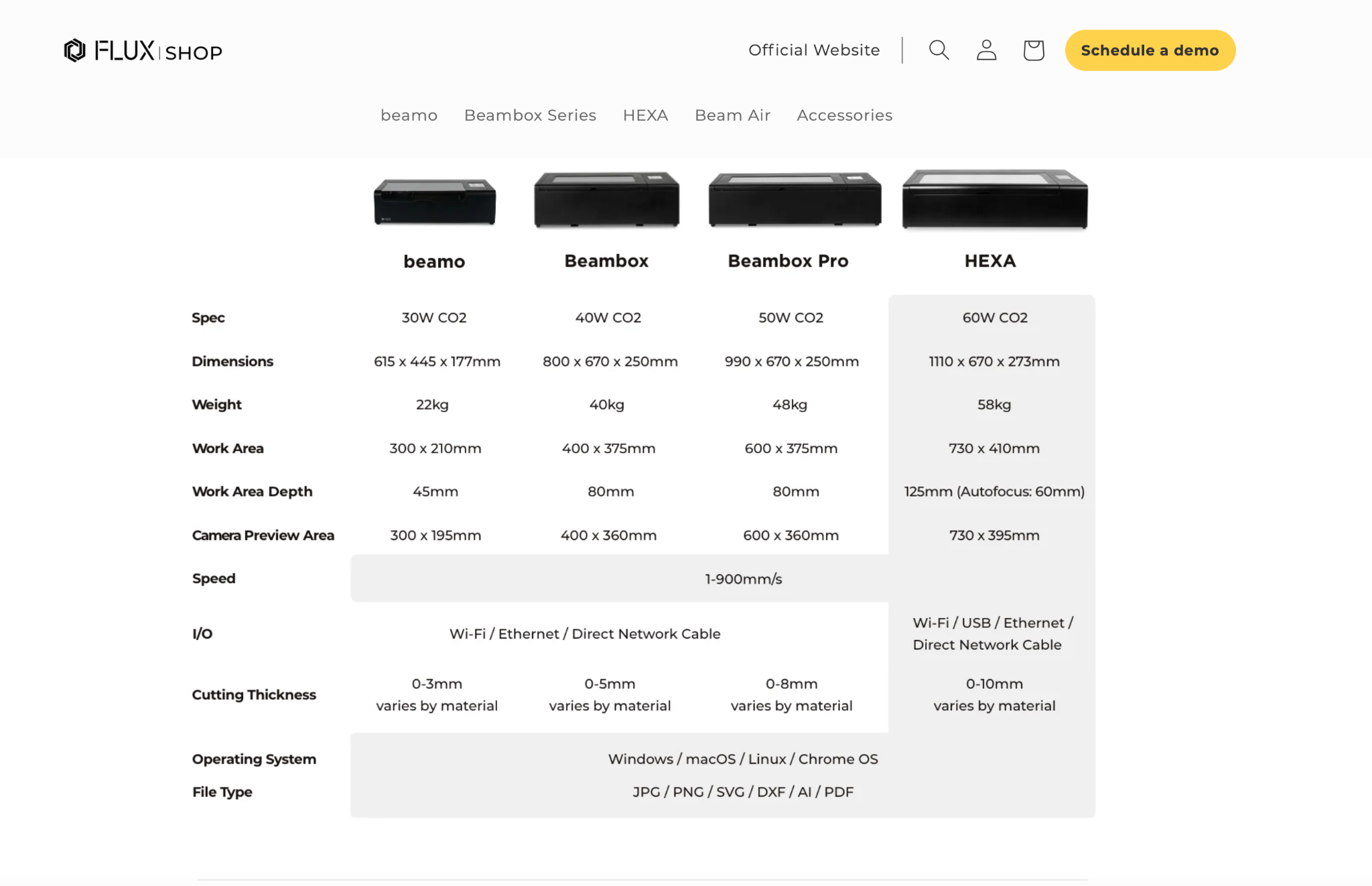

For those of you who don’t know, FLUX makes high-end, fully-enclosed CO2 lasers and laser accessories that look more like polished appliances than dangerous children’s toys.

Looking at their insane booth at FormNext, I got really excited about everything I could make with a laser, and so we got to shmoozing, one thing lead to another, and Flux was generous enough to offer me their massive 60W industrial-level HEXA unit to try out.

But before you hobbyists click away, and you pro’s get all excited, there’s good news and bad news.

The bad news is that, as I never tire of reminding you all, I have no room in this office, and I haven’t found a space I can rent just yet.

And at over 1 meter in length, not to mention a $7,000 price tag, I honestly felt like the HEXA was not as good of a fit for me, or for you guys in the audience, so while I felt like my fingers were betraying me, I wrote to FLUX and politely declined their offer. Don’t say I don’t love you guys..

The good news is that Flux also makes a super compact, fully-enclosed 30W CO2 laser called the Beamo.

What’s cool about the Beamo is that it is exactly as big as the laser tube needs to be for cooling and so on, and no bigger.

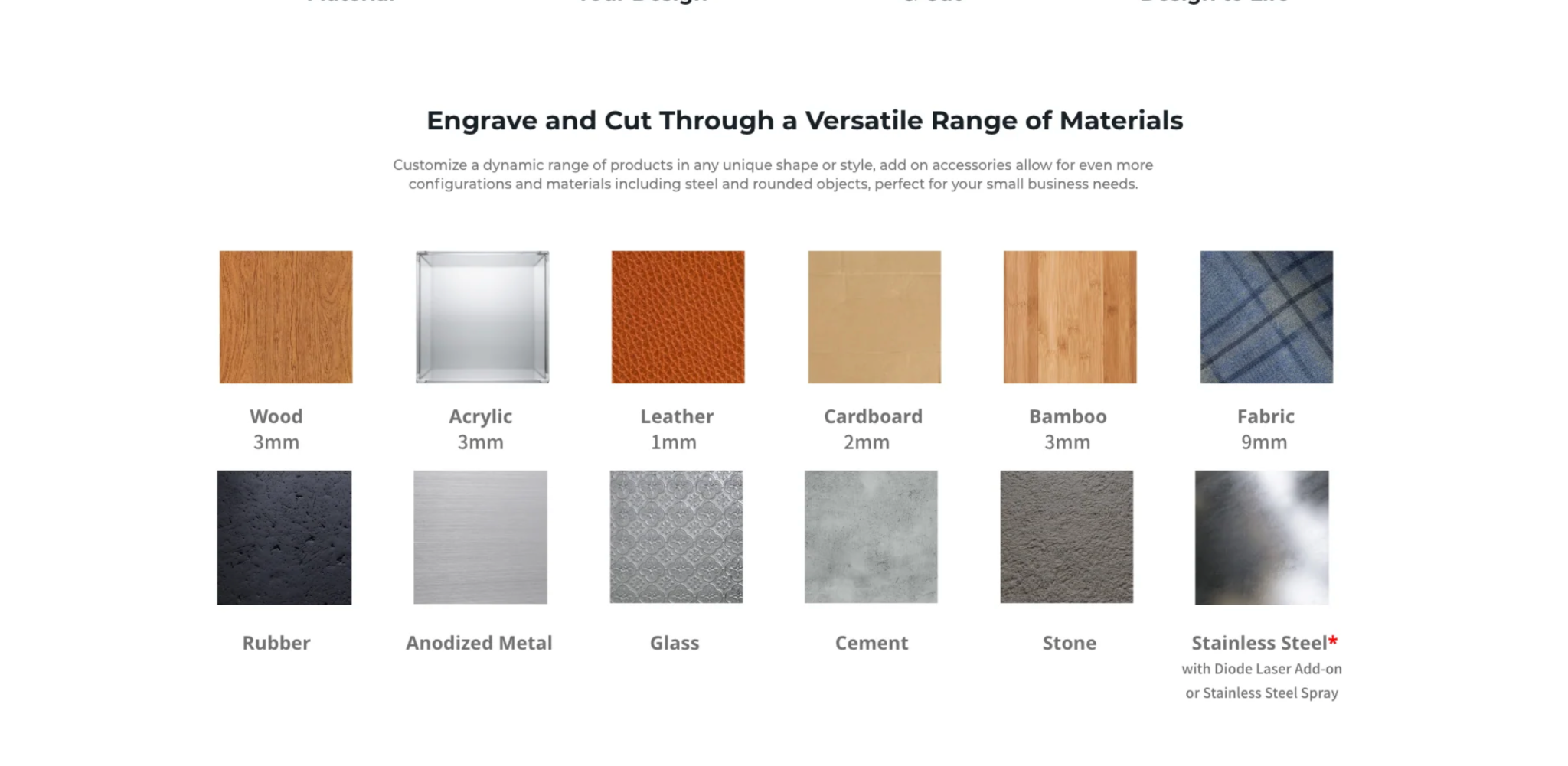

And while I still dream of cutting my own custom panels for a Voron build, or designing my own RepBox-inspired filament enclosure along the entirety of my wall using a giant laser, saner heads prevailed, and I asked Flux to instead send me the smaller, more affordable beamo, alongside their integrated FLUX Beam Air air filtration and exhaust system, which syncs up with the laser to help ensure that I don’t poison myself and my offspring with styrene exhaust fumes as I willy-nilly blast the everloving life out of every material I can find… because the beamo boasts the ability to cut and engrave all manner of thin materials, and many of them can emit toxic fumes while you do it.

Though, I definitely still smell a LOT of what I’m cutting, and this thing is incredibly loud while it’s working, so I think I probably won’t be using this in such a small space anyways.

Now, I do want to stop at this point and clarify that this is not a full review. FLUX did provide me with this unit free of charge in exchange for me doing a video about it, and while no money changed hands, this being my first laser cutter I don’t have enough experience with lasers to adequately review one of them.

So, for the rest of the article, I’m just going to be sharing my experience as a seasoned maker but laser newbie, the surprising things I learned, and also my thoughts/feelings as to whether this is a good addition to your maker repertoire.

If you want to see a full review, Stefan from CNC Kitchen did one on this exact machine, and I highly recommend it.

Getting Set Up

FLUX was kind enough to provide me with the autofocus add-on, and while that is much appreciated, I was unlucky and got one that had some kind of issue with the boards.

Fortunately, this gave me a chance to test out their customer service, and they were kind enough to connect me to Yehuda at 3DBotX, their local reseller, who literally picked it up from 2 hours away, fixed it, and dropped it off – which is a massive credit to both companies, and having gotten to know Yehuda since then, I am pretty sure that I would’ve gotten similar service – perhaps without door to door pickup – even if I weren’t a content creator.

In any case, I will admit that it took me some time to really get set up with the beamo, including aligning the laser after it’s trip up north, figuring out how the software works, and so on.

But, as you all know by now, I don’t really have anyone to blame, because I have a habit of safely storing instruction manuals in the closet – unread.

Fortunately, after going through a bunch of FLUX’s helpful YouTube videos and clips, I was able to get the laser fired up, and ready to do my first project.

So, uh…

Now What?

And here, we run into the major issue, and the reason I put this review off for months.

What the heck do I make with this thing? You see, when I first sought out FLUX and got excited about getting a laser, I had big visions of all the things I’d build. Filament dry boxes. Custom enclosures.

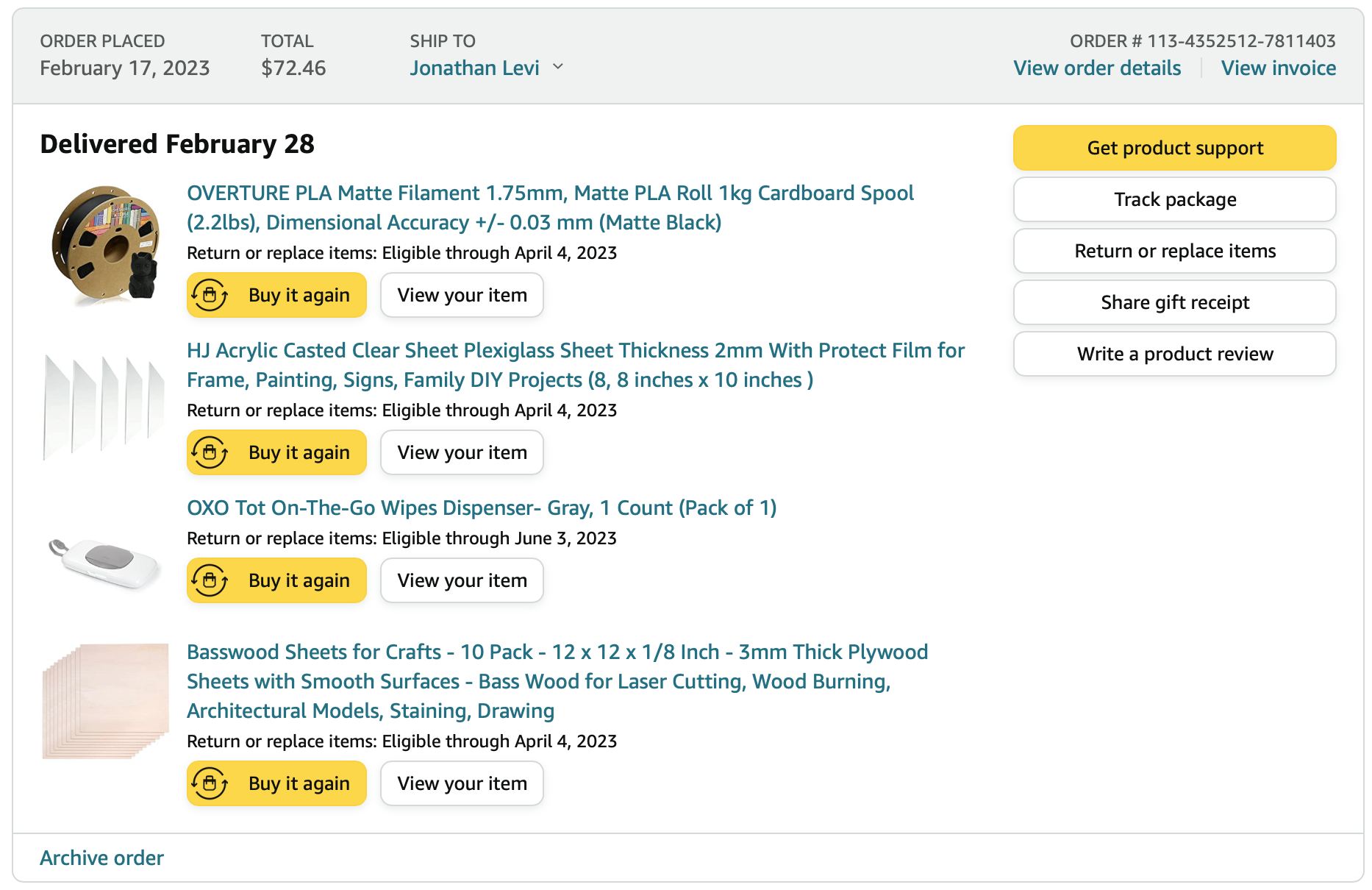

Heck, maybe I’ll cut huge wooden boards with it! Anyone want a used jigsaw? I ordered a bunch of plexiglass and balsa wood, and eagerly planned how I’d level up my maker status to multi-production-method.

But very quickly, I realized that the beamo’s relatively small work area – it’s about the size of an A4 piece of paper – meant that I wasn’t going to be “making” a whole lot of anything.

I cut a small piece of plexiglass for a window in a dry box, and designed a lovely custom reflection surface for my 3D Printed teleprompter, but then, I drew a blank.

Sure, I could cut all KINDs of craft papers, fabrics, and things like that, but I already have a Cricut Maker that I don’t use for that.

I posted on the channel’s community tab, opened up a channel on Discord asking for inspirations, but nothing came.

So I reached out to other content creators, scoured through YouTube, all in search of the answer to what exactly I could actually make with this machine.

Then, a breakthrough: I discovered boxes.py, a library of customizable boxes and other accessories that you can turn into laser cutting files, and I even made a wooden 2piece 3D Printing spool and a tissue box.

…except, coming from 3D Printing, I immediately decided that these boxes were uglier, less customizable, and a lot more manual work than just designing and 3D Printing something.

I made a filament spool using Boxes.py, but my heart just wasn’t in it. Working with wood, at least wood of this thickness, felt so limiting.

To be honest with you guys, it’s at this point that I almost gave up.

I asked myself: are desktop laser cutters just a gimmick? A novelty tool which has very little real, practical application?

Have I just become so spoiled by the possibilities of a 3D Printer, that working with thin, 2-dimensional materials has nothing to offer me?

And that’s when it hit me. A real breakthrough.

This isn’t just a laser cutter. It’s also a laser engraver.

As I dug into some of the content from creators in the laser-making space, I realized something massive.

They aren’t “making” anything.

They are customizing, personalizing, and decorating existing things.

And it was then that I realized I was looking at this machine all wrong.

I was applying an “additive manufacturing” lens to it, and trying to make something out of nothing, instead of understanding the true strengths of this machine: the ability to recklessly abuse and destroy existing materials and products.

From that moment on, everything changed.

Personalize ALL the things!

No more was I trying to find ways to use this laser cutter to make something just for the sake of making it. No more did I have a tool looking for a purpose.

Suddenly, I changed my mindset, instead looking for ready-made raw materials that I could tweak, customize, and personalize, And personalize I did.

Whereas in the past, I’d put custom-cut stickers on things with my Cricut machine, now, I could toss anything – so long as it was 45mm or thinner, under the laser and personalize it to my heart’s content.

iPad cases? Check. Wooden trivets? Check. Leather wallet? Hair brushes? Double check. Decorative cheese platters for gifts? That’s a smoking hot CHECK.

In fact, the only things I wasn’t able to customize or personalize were metal or aluminum, which I’d need a more powerful unit or diode laser attachment to successfully destroy.

Now, we were having fun.

Now you might say to yourself – Jonathan, this is ridiculous.

You’re using a $2,220 machine to do a task that you could do with a $2 magic marker. And you’re making stuff that you could probably buy at a dollar store, albeit not fully personalized.

And to that, I reply, “so?” and also, I’ll remind you that many of you (err, us) have 3D Printing storage bins that you could buy at Walmart for less.

What I mean to say is, being a maker isn’t about finding the cheapest – or even the most practical – way to accomplish a task.

It’s about being able to express yourself in whatever medium you want, to bring your own vision to life.

And if your vision involves laser-engraving yourself on the last slice of bread so that nobody else in your household eats it, well, then the FLUX Beamo is the machine for you, baby.

Just don’t try right to left text, because while it shows up just fine in the software, Your wife will probably be less than amused when you engrave her wallet with an anagram of her name.

Is It Worth It?

But in all seriousness, I think we have to now ask the question: who should get a laser cutter?

Is it worth the amount of money you’re going to spend on it, not to mention the space it’s going to take up in your shop or basement?

Naturally, all that depends on who you are and what you want to make.

If, for example, you really want to be able to work with wood, acrylic, fabric, and leather, then a laser cutter is a no-brainer.

If you really love the idea of customizing things, ranging from ceramics to different types of woods, then it makes a TON of sense.

And even if you want to add glass to your projects, it might make sense, because a CO2 laser can, indeed, engrave glass for you.

And I think it’s definitely worth asking yourself, at least, if you, like me, have a lot of 3D Printers, is another 3D Printer really going to give you new possibilities in your projects?

Is another, faster, or bigger 3D Printer going to challenge you to learn new skills and keep you engaged as much as learning a new medium or process like this will?

And yet, at the same time, you are still very much limited with what you can do using a laser cutter – or, at least – a safe laser cutter that is fully enclosed.

First, there’s the work area size, and of course, the depth of materials you can cut.

Then, there’s the fact that there are far fewer designs available out there, and much less of an “open source” culture where everyone shares their designs.

While I expected to find a website similar to Printables or Thangs, I was disappointed to find only a few low-quality sites with a handful of files, many of them requiring payment. (Yes, I know that I could design my own things from vector images, but still, to really take advantage, I’d much rather have ready to cut files), And as I said before, coming from the nearly “endless possibilities” of 3D Printing, it definitely takes some time to get used to this new tool and its limitations.

I guess, all in all, this whole experience really did make me appreciate just how versatile and powerful 3D Printing is as a maker technology.

For me, personally, I am really happy I have this laser around for when I do want to precisely cut something, and I DID get to use it for an upcoming project I have on the channel, or make a thoughtful, personalized gift for friends and family.

And I’ll admit that I’ve been eying the rotary add-on for this machine, because I’m getting really tired of my son, and, let’s face it, my wife, losing their water bottles and needing to buy new ones all the time.

And I definitely think that if I were more serious about running my Etsy shop, I could do so much more and create SO many more products with this laser cutter.

But, With all that said, I can honestly say that for my own, pretty limited hobbyist uses, I don’t think I could justify spending more than, say, $500 on a laser cutter.

That unfortunately would restrict me to a much lower quality and flat-out unsafe open design with no air filtration.

Maybe that would make sense if I were in a big, open garage or workshop which already had a fume vent, but for personal, at-home use, and with my kids around, it’s just not something I’m willing to risk.

A Message From Flux

Hey, editing Jonathan here. So, my whole family and I got sick, so I didn’t get a chance to re-record some parts of the video, but after I sent a draft to the folks at FLUX Europe, they shared with me a few points in response to some of the things I had to say.

First and foremost, in response to the fact that laser cutters are much more limiting, they let me know that it’s still really early days, and the ecosystem for laser cutters isn’t nearly as developed yet as it is for 3D Printers.

They are working on changing that by creating things like Tinkershare, which is the “Thingiverse” alternative I was looking for, and indeed, while there aren’t millions of models out there yet, I did discover some really cool ones.

They also agreed with me that a laser cutter isn’t going to replace a 3D printer, but rather, is a great compliment to it, adding new capabilities like wood, acrylic, and etching to your workflow, and that it’s better to think about them as complimentary tools, not competitive ones. Especially because with a laser cutter, it’s just going to be much, much faster to make certain things than with even the fastest of 3D printers.

One other thing that they let me know was that because of the relative simplicity of X and Y, laser cutters are a more approachable onramp into the “maker” scene, and this, combined with the safety features of a fully-enclosed laser like the FLUX beamo, makes it really popular with schools and maker spaces.

Though this review might’ve come off a bit “harsh,” overall, I agree with all of these points, and like I said, a laser pointer could be a great addition to your maker repertoire – if you have the budget.

That’s all for now, but I’ll see all of YOU on the next layer!